In recent years, the Internet of Things (IoT) has made its way into almost every aspect of our lives, and fasteners are no exception. With the integration of IoT technology, fasteners have evolved beyond their traditional role of holding things together. They have become intelligent, connected devices that provide valuable insights, enhance efficiency, and streamline maintenance processes.

Smart Monitoring and Tracking

IoT-enabled fasteners incorporate sensors, microcontrollers, and wireless connectivity to monitor and track critical parameters. For example, in the construction industry, smart fasteners can monitor structural integrity by measuring factors like tension, vibration, and temperature. These real-time data streams can be analyzed to identify potential weaknesses, predict maintenance needs, and enhance safety protocols. Similarly, in manufacturing plants, IoT fasteners can track the torque applied during assembly, ensuring proper tightening and preventing costly errors.

Condition-Based Maintenance

One of the significant benefits of IoT-enabled fasteners is their ability to enable condition-based maintenance. Instead of relying on fixed maintenance schedules, fasteners equipped with IoT technology can provide data-driven insights on when maintenance or replacement is necessary. For instance, in automotive applications, smart fasteners can monitor factors like wear, temperature, and vibrations, allowing manufacturers to optimize maintenance intervals and prevent unexpected failures. This approach reduces downtime, increases equipment lifespan, and improves overall operational efficiency.

Inventory Management and Supply Chain Optimization

IoT-enabled fasteners can revolutionize inventory management and supply chain optimization. By incorporating RFID (Radio Frequency Identification) or NFC (Near Field Communication) technology, fasteners can be tracked throughout the supply chain automatically. This enables manufacturers and suppliers to monitor stock levels, track usage, and automate replenishment processes. The data collected can be analyzed to identify patterns, optimize inventory levels, and minimize costs associated with overstocking or shortages.

Enhanced Safety and Compliance

Safety is a paramount concern in many industries, and IoT-enabled fasteners contribute to improved safety and compliance standards. For example, in the aviation sector, smart fasteners equipped with sensors can continuously monitor the integrity of critical components during flight. Any deviations or anomalies detected can trigger alerts, allowing maintenance crews to take immediate action and ensure the safety of passengers and crew members.

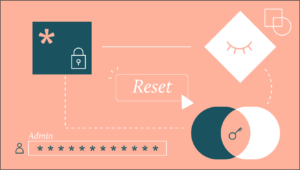

Integration with Digital Systems

IoT fasteners can seamlessly integrate with digital systems and platforms, providing a holistic view of operations. By connecting with cloud-based analytics platforms, fasteners can share real-time data, enabling predictive maintenance, performance optimization, and process automation. This integration also allows for remote monitoring and control, empowering technicians to access information, diagnose issues, and perform necessary actions from anywhere.

Conclusion

The integration of IoT technology into fasteners is revolutionizing the way we perceive and utilize these essential components. IoT-enabled fasteners provide valuable insights, enhance efficiency, and improve safety across various industries. From real-time monitoring and condition-based maintenance to supply chain optimization and integration with digital systems, the applications of IoT fasteners are vast and promising. As we continue to embrace the potential of IoT, we can expect further advancements in fastener technology, ultimately leading to safer, smarter, and more connected environments.